I’m usually not the person that shows you the latest super colorful filament, though when the first spool of this stuff landed at my doorstep, I was really intrigued. Robert, who runs RedLine Filaments here in Germany, sent me a message and teased that he’s going to send me something he’s sure I will be trying out right when I get it into my hands. Of course, I was somehow hoping for a cool new toy and was a bit surprised when I only saw two spools of filament. But this filament was different to anything I’ve ever seen available commercially.

Read MoreI recently showed you how with Bondtechs CHT nozzle you could almost print three times faster because it can melt filament way more efficiently by splitting it into three strands. The fundamental problem of heating a 3D printing filament is that the polymer conducts heat very slowly. If you print fast, the material is not yet properly heated through before it reaches the nozzle tip. By splitting the material up, you decrease the distance from the heating surface to the center of the material, thus melting it more quickly. Bondtech licensed the core heating technology from 3D Solex for their design and uses a quite sophisticated machining approach to generate the shape. When looking at the patent, you can also see other approaches to heat the filament not only from the outside but also from the inside. One is a simple bar that's perpendicular to the flow direction. Hard to manufacture conventionally, but what happens if we simply stick a piece of wire through a standard nozzle? This is exactly what I did.

Read MoreSo recently, Key from Kaika sent me a message and asked me if I’d like to take a look at their 3D printing nozzles. I get a ton of these messages and usually decline them since reviewing yet another nozzle with a special coating or alloy isn’t that interesting for me and probably also for you. The thing that excited me here though was that these are Japanese-made nozzles that you can get with an orifice diameter down to 0.1 mm, which is tinier than anything I ever used. Compared to standard 0.4 mm nozzles, this enables you to add way more fine details onto prints, though comes with challenges!

Read MoreRegular 3D printing nozzles look all pretty much the same on the inside. There is one drilled hole that’s slightly bigger than your filament diameter that goes almost all the way to the tip at which point the small orifice bore starts that defines your nozzle diameter. There is some slight variation with the cheapest ones just drilled with a standard 118° drill tip. E3D tried to improve on that many years ago with a stepped bore probably to improve internal flow but now uses as many other higher-quality manufacturers a special drill bit with a pointier tip for better flow characteristics. Ultimaker still uses a special stepped geometry in their AA-print cores maybe for less oozing during retracts. Though these are all just slight variations of a simple design.

This right here is Bondtechs new CHT nozzle that features a special core that splits up your filament into three separate channels. CHT means Core Heating Technology which means that the material is not only melted from the outside in, but also from the inside out promising higher melt rates. Bondtech is actually not the one who came up with this idea. Maybe you have already seen the Matchless nozzles from 3DSolex that have been around for a while, though never been particularly popular. Bondtech has now licensed the core heating technology and made their own version of it. They licensed it because it’s unfortunately patented by 3DSolex but I’ll get to that later.

Read MoreThis is my Cetus MK3 that Tiertime sent me more than 2 years ago and I do feel a bit bad that I never reviewed it. The Cetus was praised by many at that time for great print quality and all linear rails construction. Unfortunately, I never really liked it. Well, let’s say I liked the idea of a minimalistic machine but their control board running proprietary firmware, an oversimplified slicer, noise and only okay print quality drew me away from it. I always felt that it could do better when seeing it on my shelf, so I thought I’ll bring it back to life by simply replacing the control board and this way fixing all of my issues. I’ll cover this endeavor in an upcoming video, so if you want to learn how you can simply revive an old 3D printer, put in my case a Mellow FLY E3 with Wi-Fi, silent stepper drivers and RepRap firmware with Input Shaping in it make sure to be subscribed. In this video though I’ll show you how I was able to fix my extrusion inconsistencies because they were not solved by the new mainboard I put in it. In the end the solution was obvious, but it took me a while to get there. The fix was super simple, hence I thought I make a quick video about it.

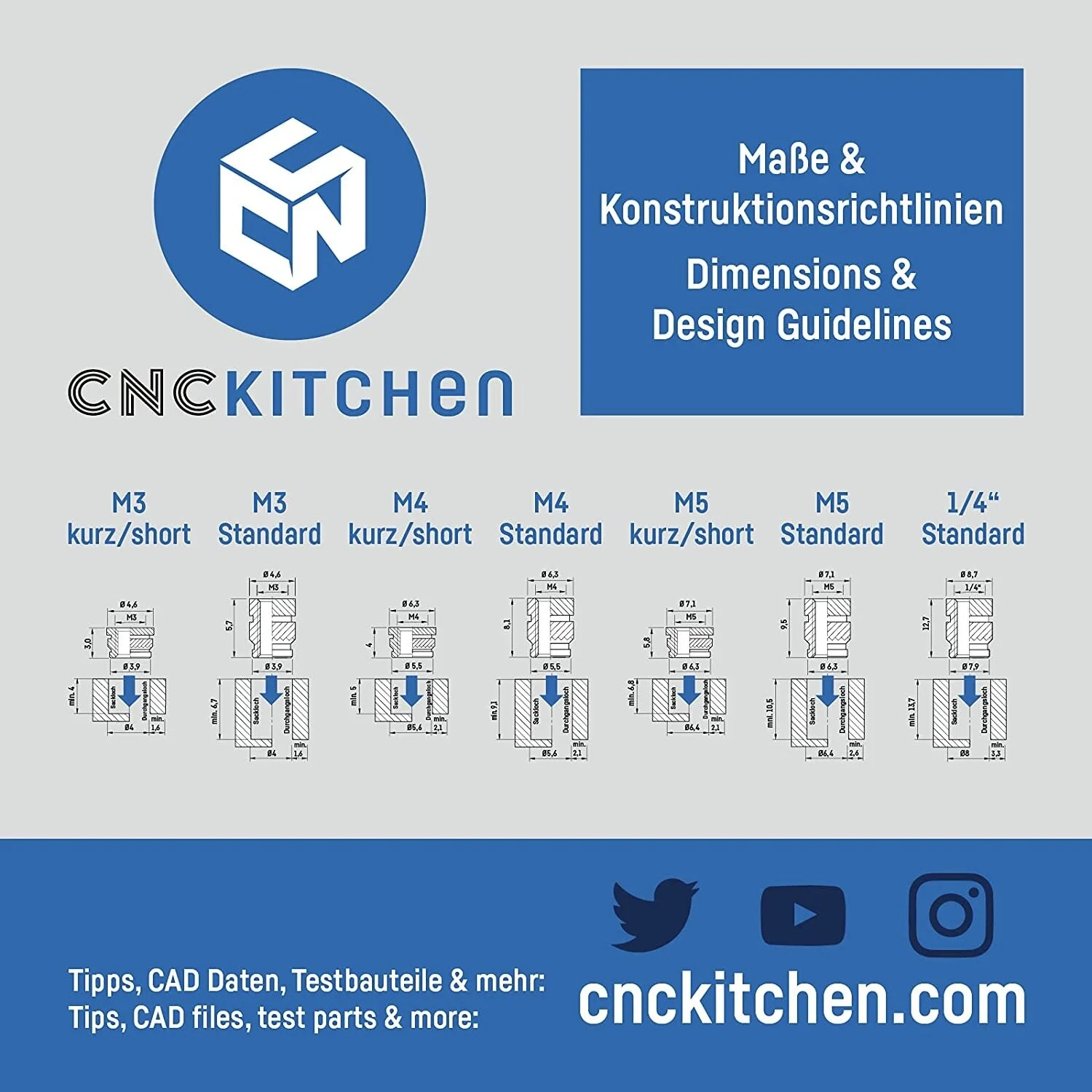

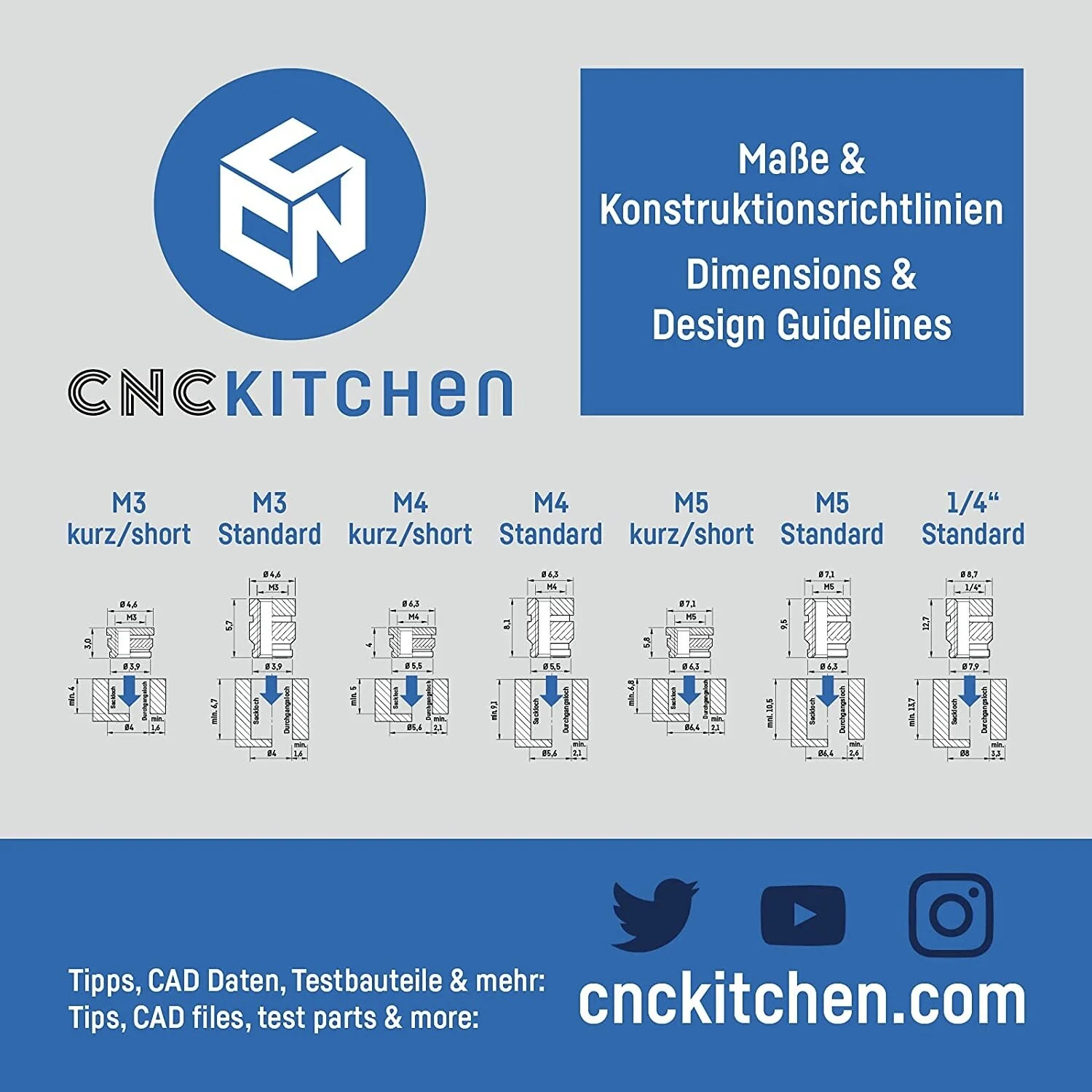

Read MoreThreaded inserts not only look great in 3D printed parts, but they also have a practical use. Everyone has had a device that was assembled with screws. After disassembling and reassembling it a few times, you realize that if the screws dug directly into the plastic, they won't hold anymore. Each time you screw the parts together, the material gets plastically deformed at the threads, which eventually leaves you with nothing but a ragged hole where nothing can grab. This is where thread inserts come into play. By melting them into your parts, they are positively bonded to the plastic and no longer move. The screws are now turned into durable and also low-friction brass and thus will last forever.

Read MoreI really enjoy my morning cappuccino, so I thought, why not use the leftover spent coffee grounds and add them to 3D printing filament. But why add coffee to a polymer? Polymer additives can be separated into three groups: reinforcing additives like glass or carbon fibers that improve mechanical properties, functional additives like plasticizer or impact modifiers which act more on a micro or molecular level and the third category which are fillers. Fillers are usually cheap materials to add volume and reduce the price of the final product. Spent coffee grounds are a filler and maybe actually pretty good ones, ecologically and economically speaking. Economically because, it’s a waste product that is widely available. Ecologically because it reduces the use of polymers and pigments and as an organic filler might even improve compostability when added to something like PLA. The coffee particles increase the surface area, absorb more moisture, and act as fertilizer during composting. I’m currently even running a composting-at-home experiment to determine what happens to biopolymers in a non-industrial compost. I’m quite curious how coffee PLA will do there.

Read MoreIf you are in a foreign country, it's immensely helpful to understand some of the spoken language. And just like on your summer vacation, if you're regularly working with 3D printers or other CNC machines, understanding how G-code is built up and what some of the instructions mean can enable you to not only fix problems but also easily customize prints to your needs.

Read MoreGewindeeinsätze sehen nicht nur toll in 3D gedruckten Bauteilen aus, sie haben auch einen praktischen Nutzen. Jeder hat schonmal ein Gerät gehabt, welches mit Schrauben zusammengebaut war. Wenn man dies einige Male zerlegt und wieder zusammengebaut hat, merkt man, dass die Schrauben, wenn sie direkt in den Kunststoff eingedreht wurden, nicht mehr halten. Jedes Mal wird dabei der Kunststoff plastisch verformt, was irgendwann dazu führt, dass man nur noch ein ausgefranstes Loch hat, in dem nichts mehr hält. Hier kommen Gewindeeinsätze ins Spiel. Durch das Einschmelzen ins Bauteil werden diese formschlüssig mit dem Kunststoff verbunden und bewegen sich nicht mehr. Die Schrauben werden nun ins haltbare und auch reibungsarme Messing eingedreht und halten somit ewig.

Read MoreI’m quite sure that almost anyone who owns a 3D printer already had a long print fail at some point just because no material somehow got extruded anymore. This is precisely what happened to me a bunch of weeks ago while filming my filament recycling video. I was easily able to continue mine with some simple G-Code trickery and thought this is actually an essential skill I’d like to teach you. Maybe even make a print fail on purpose and try to recover it with these methods before this happens with a precious 3-day print! Let me know in the comments if you ever recovered a failed print and how you were able to do it! My print failed because I had a small piece of metal in my recycled filament that at some point blocked the nozzle. In your case, you could also run out of power, encounter heat creep, have a knot in your filament, or even run out of filament without a material sensor.

Read More